NTS Optel (Nijmegen, the Netherlands) is a solution provider that develops and assembles complex optical, laser and opto-mechatronic tooling, systems, and modules. At this specialised site, we combine over more than 3 decades of experience, some of the best minds and state-of-the-art facilities. We create customized solutions for high complexity and high mix markets. Our customers such as OEMs active in the semicon, life science and analytical industry, partner with us in designing, manufacturing and lifecycle management. We do this for one-off projects as well as repeat production at speed.

Focus Areas

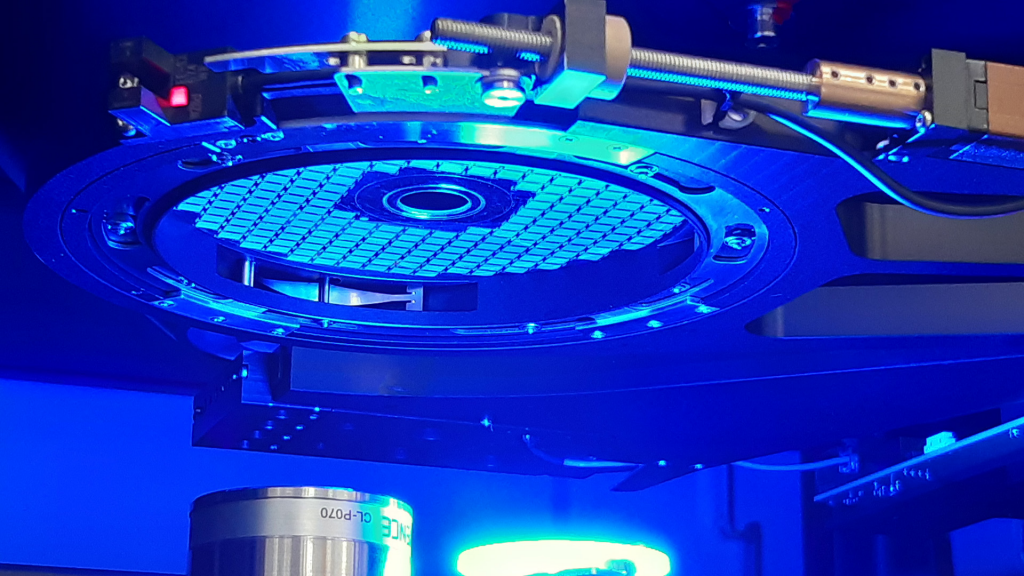

We are excited about unlocking the true value of optics for our customers. Our applications include illumination, imaging and sensing solutions, laser beam delivery as well as integrated Nanostructure testing solutions.

Taking Ideas to Manufacturability

At NTS Optel, we combine our knowledge, experience and craftsmanship to go from ideas to product. Starting from concept design, and during the development process, we keep manufacturability in mind. Having all the capabilities in-house, including domain expertise as well as optical labs and assembly infrastructure (both greyroom and cleanrooms ISO 6-7), means high efficiency/lower cost, faster time-to-market and continuous on-time delivery for our customers. Once the prototype is final we can move to small or large series inhouse production.

Whether it is an opto-mechatronic system, a module that needs to fit perfectly into your machine, or an optical measurement & testing tool, that you will market yourself or for internal use, we provide fit-for-purpose products. Regardless of whether a customer outsources the manufacturing or does it in-house, we ensure that our delivery timelines are seamlessly aligned with their supply chain.

Adding Value as a Partner

As a partner, we always keep our eye on your success. First and foremost, we focus on our customers’ needs and what is important for them. We use our multi-disciplinary expertise to address that need – whether it is design, development, engineering or manufacturing. Along with our customers, we work on the idea, add our engineering expertise and create new (optical) solutions. Our proficiencies in optics, electronics, software and mechanics constantly push the boundary of what is possible, allowing applications in ever smaller dimensions. This enables increased usability and lower cost, which we can then pass on to our customers. We strive to be one of the top 3 partners, for custom optical, laser and Nanostructure testing solutions.

Download our brochure:

This Brochure offers a captivating introduction to NTS, highlighting our exceptional capabilities in the field of optics. Discover our expertise, explore our focus areas, and witness how we transform ideas into reality.

Brochure – Accelerating the future in the world of optics

NTS Optel in Numbers

0

0

Optics

We are excited about unlocking the true value of optics for our customers. NTS develops, manufactures and assembles customized opto-mechatronic systems, optical measurement and Nanostructure testing solutions. For this we rely on our domain expertise and state of the art facilities.

System Assembly

From Rapid Prototyping and New Product Introduction to Series Assembly and Cleanroom Assembly we excel at creating solution to customer requirements.

Read moreContact

Want to know more?

In case you would like to contact us, you can fill in the contact form here. We will respond to you as soon as possible.Location

Transistorweg 8

6534 AT Nijmegen

The Netherlands

+31 (0)24 352 17 01

Jobs at NTS Optel

Read more

Technologies

We possess knowhow about various technologies such as vacuum and cleanliness.

Read moreFocus Areas

We develop, produce and assemble (opto-) mechatronic systems and mechanical modules.

Read moreAbout NTS

With our global presence and technological expertise, we push the boundaries of possible.

Read more